Works

Published at 30/03/2017

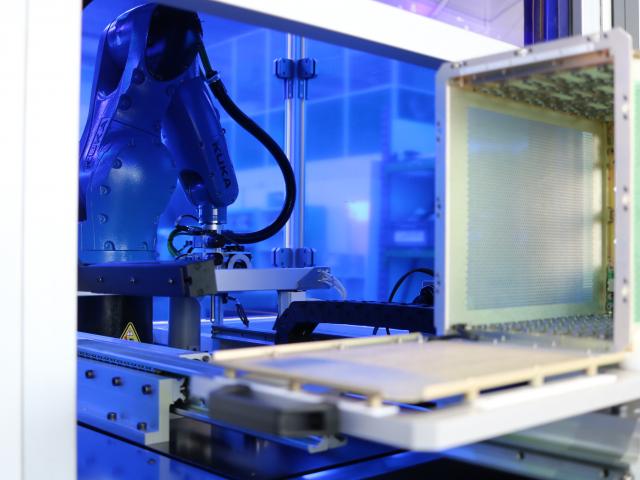

Control cell

Production equipment

Our client’s request was to automate the quality control of its mistake-proofers in order to obtain 100% of the production controlled and a reduction of the waste down to 400ppm (parts per million).

We studied and realized an automated mean able to control the presence and positioning of the internal mistake-proofers (for the electronic boards), but also able to control the external ones (receiving the plane connection). The machine controls a product in less than 5 minutes, generates and transmits traceability data.

Controls done:

- Control of the positioning and the colour of the mistake-proofer

- Control of the fixing of the mistake-proofing

- Control of the electronic boards (attached manually by an operator)

- Generation of a control file indicating if every mistake-proofer was placed correctly or not, with the possibility to have an evidence picture for the client if needed.