Production equipment

Our automation solutions for your industrial processes.

We offer turnkey and tailor-made optimization solutions to maximize your industrial performance and control your production costs right from the conception of your products.

Whether you are looking to optimize your service rate, your flexibility, your safety or your ergonomics, we offer you the best of our mechanical expertise to guarantee your performances. We assure the start-up until the complete installation of your equipment in your factories in France or internationally.

To accompany you in the modernization of your workshops of manufacture, transformation and assembly.

With more than 25 years of experience and more than 500 pieces of equipment delivered, we have developed a complete range of modular functions, with enhanced reliability and safety that we can integrate into your means of production. Our R&D activity associated with a permanent watch allows us to offer you the best of today’s technologies.

Functions:

LASER, INKJET & THERMAL MARKINGS / DIMENSIONAL CONTROL / MEASURE / AUTOMATIC DISTRIBUTION / VISION / MOTION / HYDRAULIC / ROBOTIC / INDUSTRIAL COMPUTING / NUMERICAL CONTROL / LEAK CONTROL / RIVETING / Snap-riveting / ELECTRICAL SCREWING / UV HEATING / INDUCTION / DOSAGE / SPRAYING / LASER MICRO-MANUFACTURING / TRACEABILITY / JOINT PRESS MACHINE

Years of experience in mechanical industry

Number of employees

Years since the creation of the REOREV Group

Turnover in millions of euros

In the respect of your preferences, we create complete assembly lines that we co-develop with you on the basis of both 3D and real life mockups. We treat each work zone to incorporate them to the complete product with the permanent requirement to improve its usage and safety.

We develop processes which allow the fast change of the series for a service rate higher than 95%.

See examples

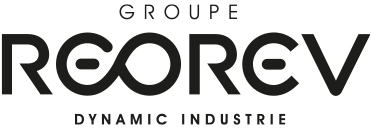

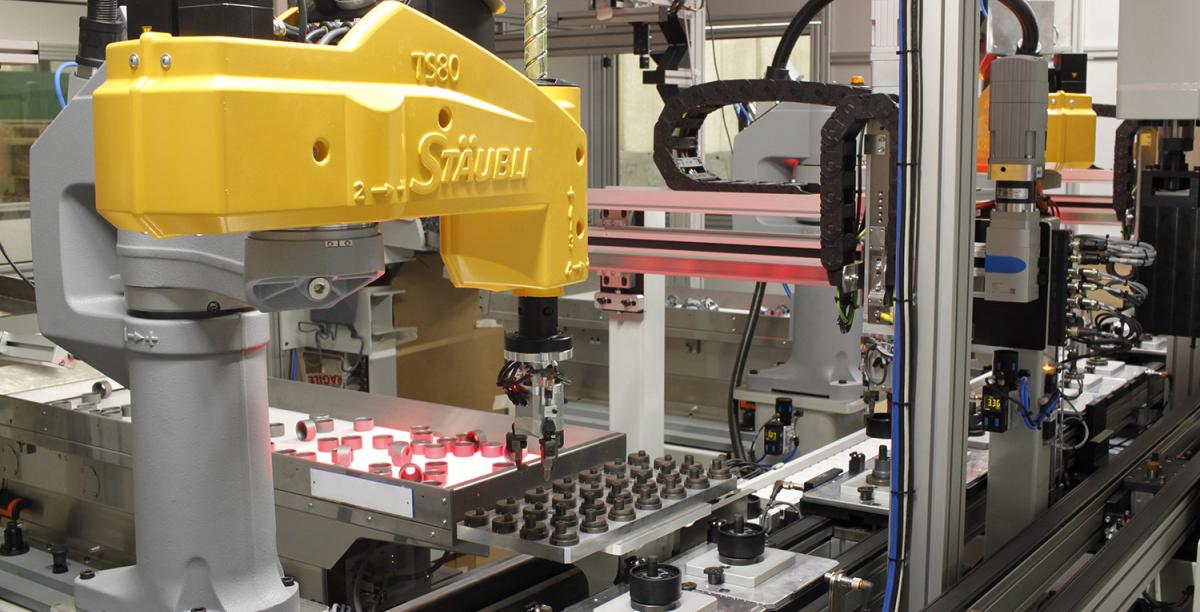

To improve your productivity, simplify the tasks of your operators or reduce the rate of musculoskeletal problems, we create cells and robotic cells which respect your preferences and the applicable standards. We incorporate any type of robot and arrange the automatic functions in the most efficient way.

Ergonomic and robust, our equipment is also maintenance friendly, and is conceived to blend in at your production site and to evolve depending on your needs. We are attentive to the finishing touches and the design to give your factory a more positive image.

See examples

We study, design and draw your custom-made production machines by integrating the functions necessary for your processes. The equipment designed is developed and assembled in our workshops, and its performance is tested in accordance with the specifications.

We assure you the start-up until the complete installation of your equipment in your factories in France or abroad.

See examples

We meet the needs of machine shops, manufacturers and processors. Our automation solutions on lathes or machining centers improve the yield, the efficiency and boost the capacities of your machine park.

We offer standard and specific applications that allow the linking of several series of parts in complete autonomy.

See examples

You wish to mechanize and automate charges shifting operations from one point to another; we offer you judicious and original technical solutions which will improve your workflow. We offer you reassuring and ergonomic means, able to preserve the quality of your products. With 20 years of experience in the handling and computer-integrated material field, we have acquired a real knowledge which permits us, among other things, to respect our production deadlines.

See examples

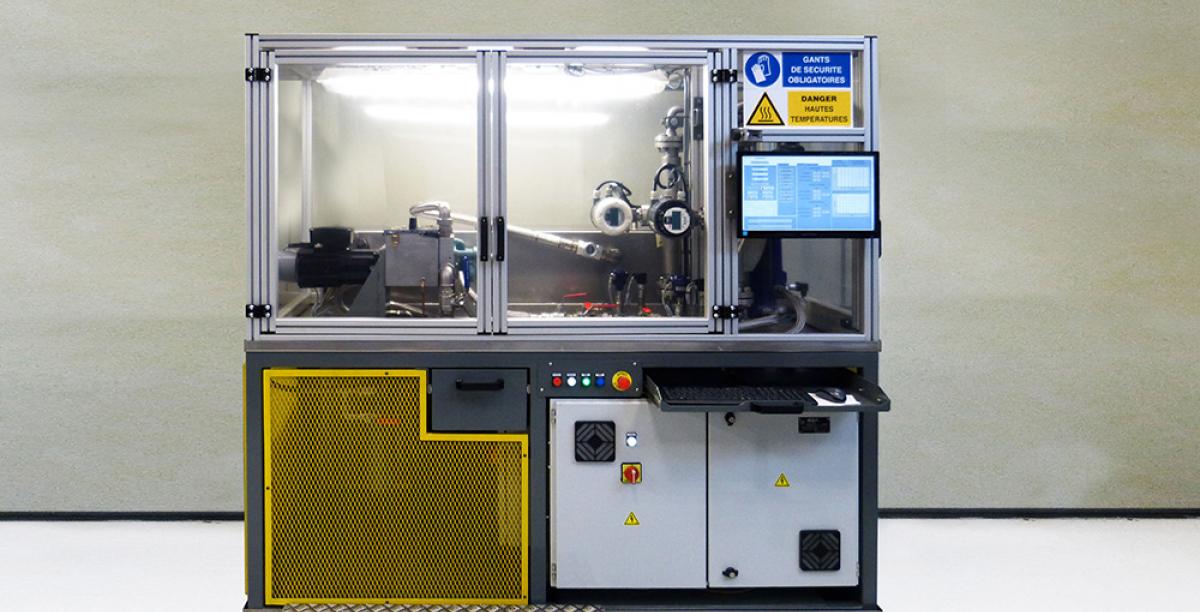

We create specific equipment to validate and qualify your products: test benches which blend in with your process to maximize control’s speed and reliability. We know how to implement your most specific demands to ensure the conformity of your products, to allow a flawless, regular and permanent use of your equipment.

We can also develop test benches able to carry out vibration, endurance and tightness tests.

See examples

We have been working for more than 15 years with renowned French and European parks and have been able to meet their scenic, technical and budgetary requirements.

Our expertise in the industrial world allows us to guarantee you the best solutions to optimize your investment and operating costs.

See examples