Industrial product development

Our vision.

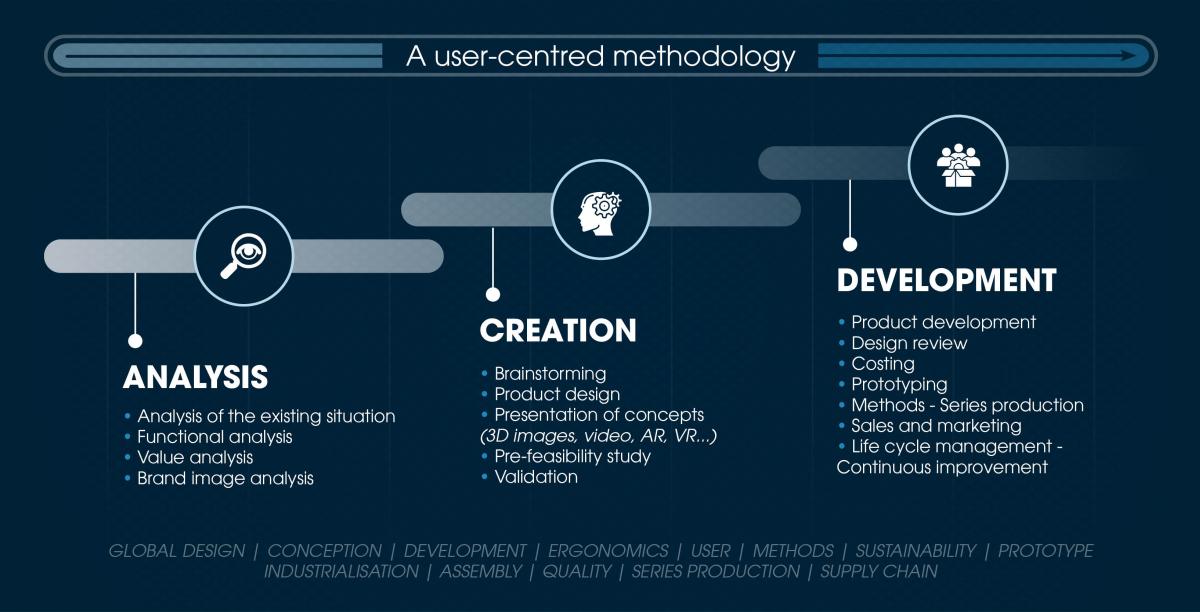

At REOREV, our priority is to adopt a global design strategy focused on the user in all our industrial projects. By including this methodology from the start of the project, we offer our customers a complete and reliable vertical solution from product design to mass-production.

From product design to series production, in France.

Our commitment extends to the entire process, from initial development, through industrialisation, right up to manufacture in our workshops in France. We take a global view that includes every stage, with complete turnkey delivery. This approach ensures optimum efficiency and consistent management at every stage of the project.

The Industrial Product Development team has decades of experience of working on ambitious and sometimes complex projects. This diverse expertise enables us to take on each challenge with confidence and enthusiasm, ensuring the success of every one of them.

Over the last ten years, our workshops have produced 80,000 finished items from more than twenty separate projects. Each product is the result of a meticulous and carefully orchestrated process, reflecting our commitment to excellence and quality.

Our global approach for optimum results:

- A people-centred approach through product design,

- Vertical integration that simplifies your procurement process and guarantees continuity throughout the product life cycle,

- Customised, innovative solutions,

- The skills' versatility of an industrial group,

- Solutions from other fields re-appropriated for your own benefits,

- A differentiating factor driven by a passion for what has never been done before.

By entrusting your projects to REOREV, you can concentrate fully on your commercial development by freeing yourself from the constraints associated with the complexity of design and series production.

VALUE ANALYSIS / FUNCTIONAL SPECIFICATIONS / TECHNICO-ECONOMIC FEASIBILITY STUDY / CONCEPT RESEARCH / BRAINSTORMING / DESIGN / AMDEC / TECHNICAL STUDY / OPTIMIZATION / DIMENSIONING / MANUFACTURING FILE / PROTOTYPE SUPPLY / FINE-TUNING / INDUSTRIALIZATION SUPPORT

Agreements.

THANKS TO OUR RESEARCH TAX CREDIT ACCREDITATION, YOU CAN BENEFIT FROM PARTIAL FUNDING FOR YOUR R&D PROJECTS.

Years of experience in mechanical industry

Number of employees

Years since the creation of the REOREV Group

Turnover in millions of euros

Conceive to produce

As a true contractor in product development, we follow your requirements in order to support you from creation to chain-production by optimising quality, cost and delivery time until the final industrialisation process in our workshops.

REOREV's development of industrial products offers a complete turnkey service.

A global design strategy

We apply a reliable methodology that consists of studying each project under the spectrum of innovation, which has been the REOREV Group's DNA for over 50 years.

Centred on the user, our strategy considers the entire life cycle of the product. We obviously keep in mind its uses, but also its manufacture, its context and its end-of-life in order to minimise environmental consequences.

Our passion for what has never been done before is a true motivation to promote individual and collective initiatives. This pushes us to rethink what already exists, mix our knowledge on various disciplines together, and therefore create the unexpected.

GLOBAL DESIGN is on the one hand, a macroscopic consideration of the entire product ecosystem and, on the other, a microscopic approach to perfect every detail.

Who can benefit from this offer?

You are:

- An industrial company choosing to outsource the design, engineering and production of one of its products,

- A FABLESS start-up with an ambitious, realistic project, backed up by market research and a well-received POC, looking for an industrial partner,

- A VSE/SME victim of its own success that lacks the human and material capacities to keep up with the demand for research and production,

- A SME or Multinational with a need for industrials tools that can carry out their products delivered in large series to their customers,

- A local or regional authority that wishes to incorporate global design thinking into their urban development plan,

- An award-winning inventor who has raised the funds to turn his idea into an industrial reality,

✔ We'll have an answer tailored to your needs.

You have:

- A fabless strategy: business development, marketing and distribution are your areas of expertise. You outsource the rest,

- A specific need to produce in small or medium series outside your core business, for which you want to outsource product designing and manufacturing,

- A need for industrial tools catered to your mass-produced goods to facilitate their distribution and implementation. You are looking for an established industrial partner to develop this tool because this is outside of your expertise,

- You've got an idea, a proven concept, a promising market analysis and you've raised funds, but you don't have the skills in design / product development / production / assembly. You need an industrial partner to support you from Proof Of Concept to series production,

- You have issues with a product or process and are looking for a way to improve your results by investing in innovation,

- You are required to meet standards or comply with a directive and you don't have the time or the knowledge to develop and mass-produce the solution,

- Or you simply have questions about the "make or buy" of a product in your catalogue,

✔ We are your right hand when it comes to design, conception, prototyping, development, industrialisation and series production in our workshops. Focus on developing your business. We'll take care of the rest.

Industrial tools’ development

Did you know? We also develop products linked to industrial tools! Explore our creations by following the link below and discover how we can transform your ideas into concrete industrial success.

See examples

Renewable energies products’ development

Did you know? We also develop products powered by renewable energies! Explore our creations by following the link below and discover how we can transform your ideas into concrete industrial success.

See examples

Solar powered products’ development

Did you know? We also develop products powered by solar energy! Explore our creations by following the link below and discover how we can transform your ideas into concrete industrial success.

See examples

Mass-produced goods’ development

Did you know? We also develop other mass-produced goods! Explore our creations by following the link below and discover how we can transform your ideas into concrete industrial success.

See examples