Machining and assembly

Your externalized and secure factory.

More integrated, connected to the Core of territories and close to the actors of its ecosystem (clients, subcontractors and suppliers), tomorrow’s factory will contribute to the stimulation of a network and a local economy. We can manage Rank 2 suppliers and invest to accompany you in your developments.

The culture of continuous improvement.

Having a culture of excellence and expertise as a leading integrator, we configure your means of production specifically for you and ensure the service rate and the quality while considering the entire supply chain. We anticipate your needs and schedule a permanent investment program of our means of production.

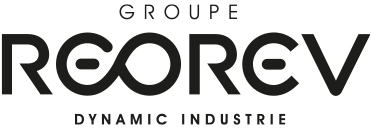

A perpetually evolving machine park.

TWIN-SPINDLE LATHE, THREE TURRET / ROBOTIZED 5 AXIS DRILLING CENTRES / TOOL TURRET / ELECTRO-EROSION / FLAT AND CYLINDRICAL RECTIFIER / 3D PRINTING

Years of experience in mechanical industry

Number of employees

Years since the creation of the REOREV Group

Turnover in millions of euros

Prototyping

You wish to quickly and efficiently transform innovative ideas into successful final products? With our tools adapted to the production of unique pieces, we can make functional prototypes that will comfort you in your design choices. We accompany you from the experimental model to the pre-series prototype.

Therefore, you will be able to start a prospecting phase and show your potential the purpose of the product through near reality tests. A true marketing lever!

See examples

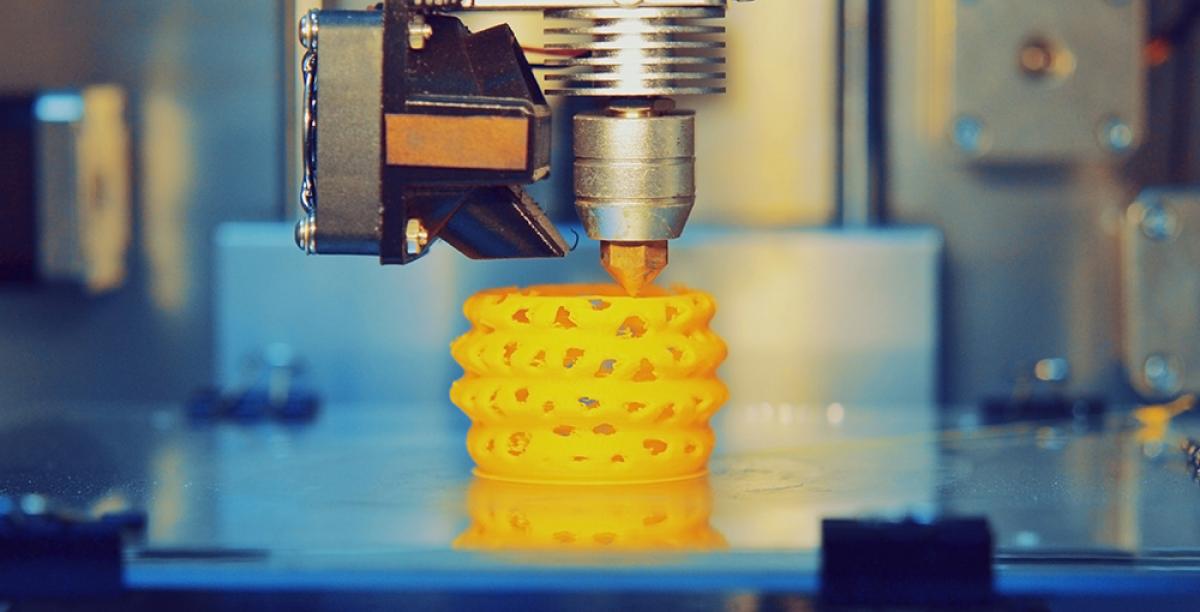

Products and subunits

Our job expertise allows us to carry out the realization of complex and technological products. From small to medium-sized production, for complete products or subunits, you benefit from an agile and available factory, able to suit your rates of work. Moreover, we can counsel you and offer you improvements on your products.

All your products are controlled and tested with our measuring tools (continuity, isolation/dielectric…) before delivery in your factories. We thus ensure the quality of manufacturing.

We keep your dedicated tools in stock in order to secure your production. We anticipate your need to offer you great reactivity along with optimized costs.

See examples

Assembling, Wiring

We implement special assembly and wiring cells dedicated to your products, and we are available and operational depending on your production needs and guarantee certified and quickly delivered products.

See examples

Tools and complex parts

Thanks to the expertise of our tool mechanics and to the diversity of our machine park, we can make technical components for your production lines. We counsel you to elevate the quality of your products and are recognized as such in the healthcare and aeronautics fields which are known for requiring perfection.

See examples

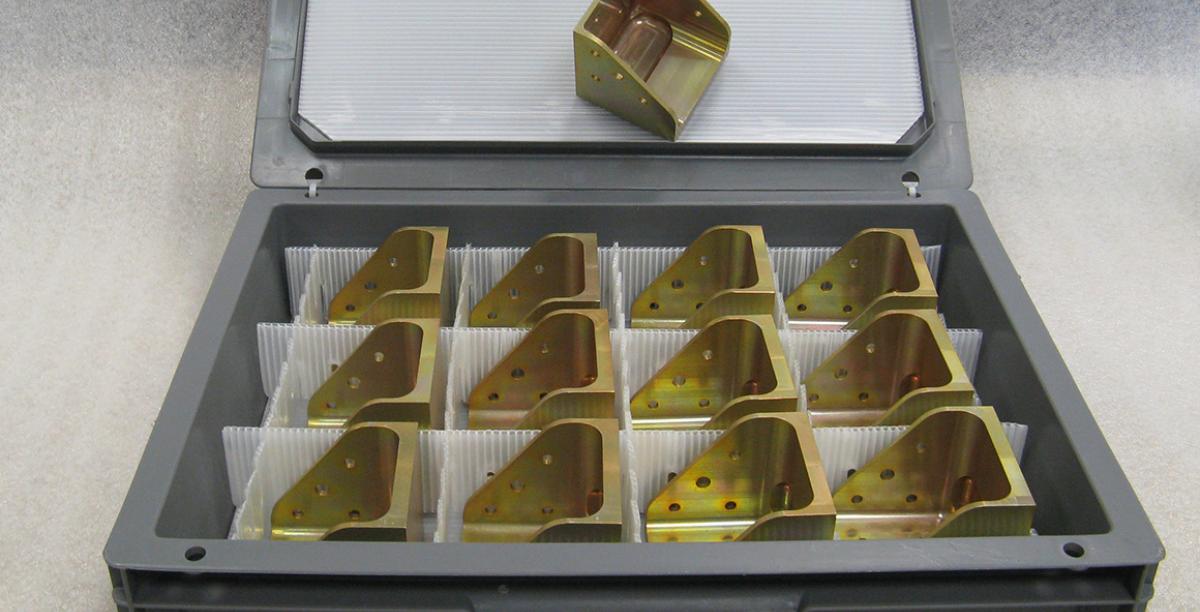

Mass-produced machined parts

Creating perfect pieces has been our “raison d'être” since 1966. Recognized internationally for the machine quality of our pure iron items, we provide you with passionate and perfectionist expert technicians, as well as a machine park and high-tech multi-spindle machines. We care about the cosmetic aspect and guarantee you the packaging’s safety while delivering finished parts (thermic treatment, surface treatment, assembling) in solid and reusable containers, adapted to your products and line of production.

See examples

Supply chain management

We are experts in activity planning, stock management, physical and information flows management to optimize the processes of orders and deliveries. Our industrial logistics guarantee just-in-time delivery in short cycles, in pull flow according to your demands.

Gift yourself the culture of excellence and quality advantages with no additional cost.

The continuous improvement of our working tool is an approach that we have planned through the development of investment programs. They were created to anticipate the future needs of our customers and constantly enrich our services.

See examples

Flexible factory

We established an industrial organization so we can adapt to your needs and use reconfigurable production tools.

To be more responsive to your requests, we permanently have a stock of raw materials according to your needs. Our logistic platform is installed in the same locals as our production unit, which allows us to reduce delays significantly.

As an active partner, we engage ourselves in your footsteps of continuously reducing delays.

We manage your catalogue of products, while reducing the number of your suppliers and your acquisition costs.